Expertise to accelerate your speed-to-market

Our streamlined production model allows us to meet your packaging deadline, all while adhering to your specifications and without sacrificing our signature quality control and attention to detail. Our centralized, end-to-end manufacturing processes not only creates cost savings for you from your folding carton jobs, but also accelerates the speed-to-market for your products.

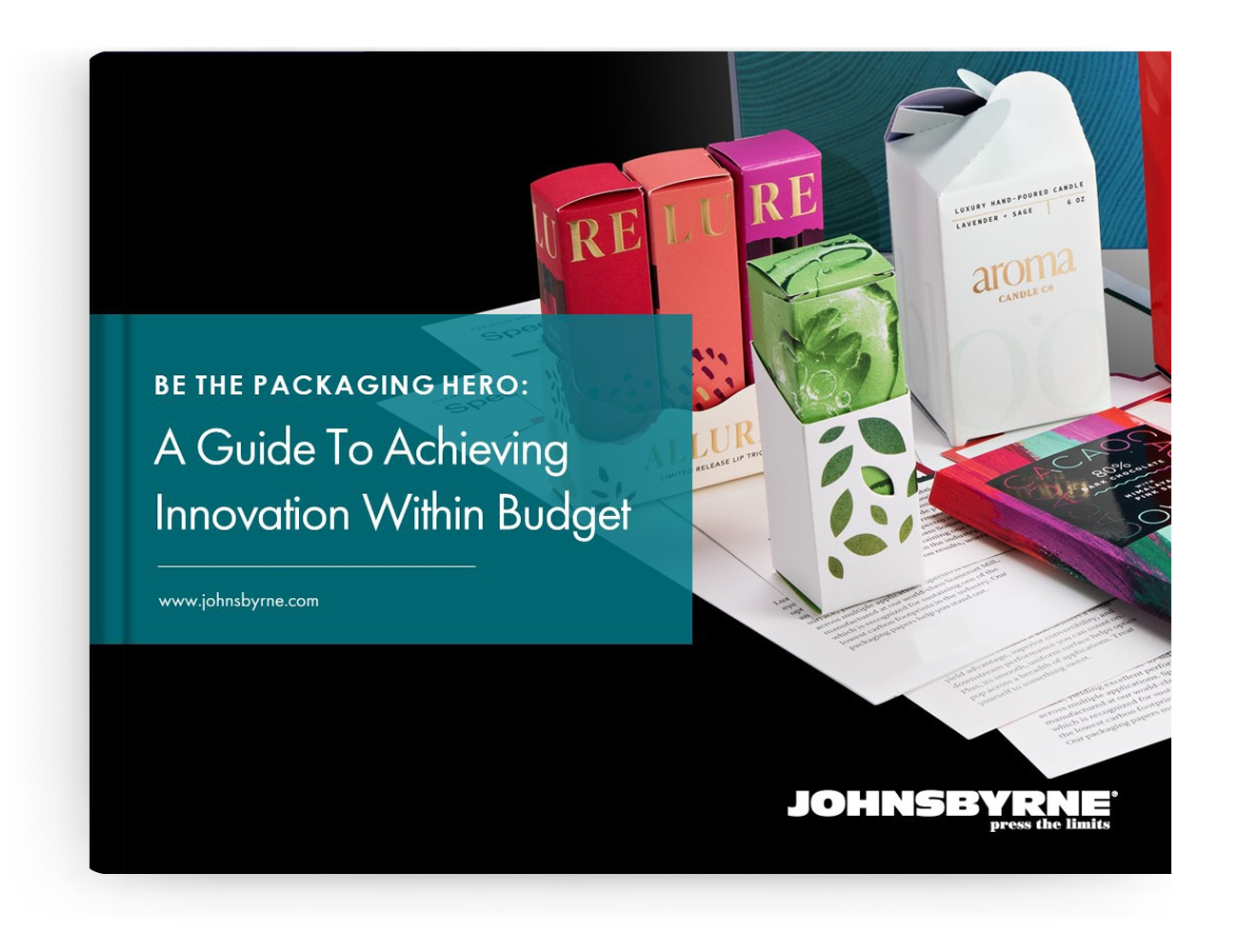

The only limit is your imagination. And at JohnsByrne, as a premier folding carton manufacturer, we can press that limit to limitless with our selection of folding cartons, which include:

- Paper Folding Cartons: JohnsByrne has created paper folding cartons for some of the world’s most recognizable brands across multiple industries. Our beautifully designed, custom paper folding cartons are expertly created with the needs and mission of your business in mind.

- Plastic Folding Cartons: Let your products shine with our clear plastic carton packaging that highlights what’s inside. Our team will collaborate with you to produce a design that effectively displays your products and accents their most attractive features.

- Custom Folding Cartons: We create custom packaging with your products in mind. Our team can present you packaging complete with one-of-a-kind cutouts and specialty coatings that attract and engage.

- Luxury Folding Cartons: For our decorative and luxury packaging options, we bring you the best finishes, effects and structural designs. Whether your company already has an idea for your luxury packaging product or need our expert advice to create one, JohnsByrne is there to make your brand the best it can be.

- Sustainable Folding Cartons: Our folding cartons are designed with sustainability in mind including structural engineering, materials, and recyclability to minimize environmental impact and help meet your sustainable packaging goals.

Recent Work View Gallery of Work

Bring your brand’s packaging vision to life

Whether you have a particular vision in mind or need guidance in formulating your folding carton packaging design, JohnsByrne is there for you. When designing your standard or custom packaging, you can count on our manufacturing to turn your idea into a reality through a simple, synergistic process focused on:

- Early Collaboration: Our team of packaging specialists will work with your company in the early development stages of your project all the way to completion.

- Conceptualization: We’ll examine your folding carton specifications and ask questions with the end result in mind.

- Execution: With the design finalized, our end-to-end manufacturing teams and ISO 9001:2015/ G7 certified processes execute your jobs flawlessly and with unparalleled quality.

Rely on our robust folding carton capabilities

At JohnsByrne, we have created unforgettable packaging for some of the world’s leading companies, so you can trust we will create folding carton packaging to stand out in all the right ways. As your packaging partner, we have the expertise and know-how to create effective and high quality packaging including:

- An ISO 9001:2015 and G7 certified facility

- A modern pressroom that produces breakthrough visual and tactile effects

- Comprehensive converting equipment for all your finishing needs as well as assembly and fulfillment capabilities

- We also have proven expertise to take your packaging from ordinary to extraordinary by:

- Printing on exotic/difficult substrates and litho mounted corrugate

- Providing anti-diversion coding

- Meeting folding carton validation requirements, such as COP, drop and rub tests

What is the folding carton manufacturing process?

The folding carton manufacturing process involves the following steps:

- Die-Lines and Sheet Layout: Die lines will show where die-cutting, folding and gluing will occur and will also show where artwork is positioned for printing. die-lines are then used by pre-press departments to build the ‘sheet layout’.

- Printing: During this stage, the paperboard is run in the most effective grain direction. During the printing process, ink & coating units will be used to apply color, innovative textures, and other visual effects.

- Post-Press Finishes: any remaining visual effects such as hot foils or emboss/debossing will be done post-press using hot foil stampers and emboss/deboss machines.

- Die-Cutting: The die is an elaborate, powerful cookie cutter used to cut many duplicates of the layout out of a sheet of paperboard and to minimize waste. When the individual cartons have been cut out of the original sheet, the remaining stripper paper is separated for recycling.

- Folding / Gluing: flat, die cut pieces will be fed for folding, pre-breaking, and gluing.

Learn more about the folding carton manufacturing process.