In today’s competitive market, packaging does more than just protect a product; it tells a story, engages the senses, and leaves a lasting impression on the consumer. At JohnsByrne, we specialize in creating packaging solutions that not only meet functional needs but also elevate your brand to new heights. With a wide range of premium coatings and finishes, we can transform ordinary packaging into an engaging consumer experience. In this guide, we explore 20 of our most impactful finishes, detailing their visual and tactile qualities, best use cases, and the unparalleled value they bring to your packaging.

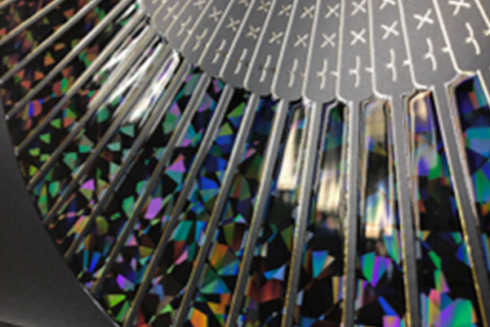

1. CAST & CURE

Cast & Cure is a unique holographic effect that adds a sparkling, multi-dimensional finish to your packaging. This technique involves applying a UV coating and a specialized film, which is then cured to create a dazzling holographic pattern. During the process, a patterned film is pressed onto the wet UV coating, which is then cured under UV light, transferring the pattern onto the surface. The result is a captivating, high-gloss effect that enhances the visual appeal of any product.

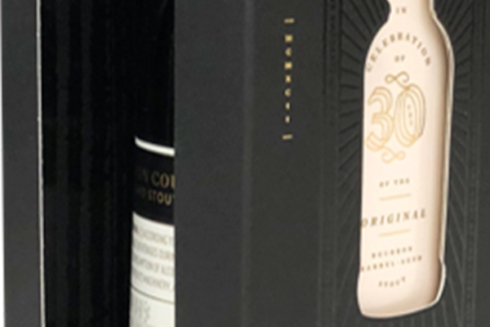

2. DIE CUT

Die cutting allows for the precision cutting of packaging materials into unique shapes or intricate patterns. This technique is perfect for creating windows or adding interactive elements to your packaging design. Die cuts are commonly used in promotional packaging, collector’s editions, or highlighting specific product features.

3. DOUBLE DIMENSION

Double Dimension is a sophisticated layering technique that creates a striking 3D effect on the packaging, adding depth and visual interest. This process involves precisely layering multiple materials or coatings, which results in elevated design elements that stand out from the surface. By emphasizing key features like logos or graphic details, the Double Dimension finish draws attention and enhances the tactile experience, creating a captivating interaction between the consumer and the package. The added depth and texture offer a premium look and feel that elevates any product.

4. EMOTE COAT

Emote Coat is a dynamic coating offering an engaging sensory experience. The technology imitates the animation and movement of a lenticular, for a fraction of the cost, and is achieved with a single-pass on-press technique. This tactile transformation invites consumers to interact directly with the packaging, making the product more memorable and engaging. The shift in texture enhances both the visual and physical experience, drawing attention and encouraging further exploration of the product.

5. GLITTER

For a stark and bold look, glitter coatings are the way to go. Glitter coatings are made when large glitter particles (50-200 microns) are added into UV gloss coating. They also come in a wide assortment of colors. Glitter coatings command and demand attention especially when they are applied and contrasted against a more subtle area of the packaging like the luminaire on the right. It is also easy to see how brilliantly the glitter effect is magnified when a light source is put behind it.

6. GRIT / SAND COATING

Grit Coating applies a textured, rough surface to packaging, giving it a rugged and durable feel. This process involves adding tiny particles to the coating, creating a sandpaper-like finish that enhances grip and tactile engagement. The rough surface not only provides a functional benefit but also adds a distinct visual and sensory element that sets the packaging apart.

7. HOLOGRAPHIC

Using a holographic foil or rainbow foils give the package or piece the ability to change color combinations when viewed at different angles. This is a great way to add a pop of color to solid packages. Holographic foils provide a fun and sophisticated flair to product packaging.

8. HOT FOIL STAMPING

Hot Foil Stamping is a refined technique where a thin metallic foil is transferred onto the surface of packaging using heat and pressure. The process involves placing the foil between a heated die and the material, bonding the foil to the surface in intricate designs. This method produces a smooth, reflective finish that shimmers when it catches the light, available in various metallic hues like gold, silver, copper, or even holographic patterns. The result can range from bold, attention-grabbing accents to subtle, elegant details, enhancing the overall aesthetic of the packaging.

9. COLD FOIL

Cold Foil Stamping is a versatile alternative to Hot Foil Stamping, delivering similar metallic effects without the need for heat. Instead of using heat and pressure, cold foil involves applying a metallic foil to the packaging material using a special adhesive that is cured with UV light. This allows for faster production times and makes it ideal for high-volume projects. The overall finish is sleek and lustrous, perfect for enhancing packaging that demands both speed and visual impact.

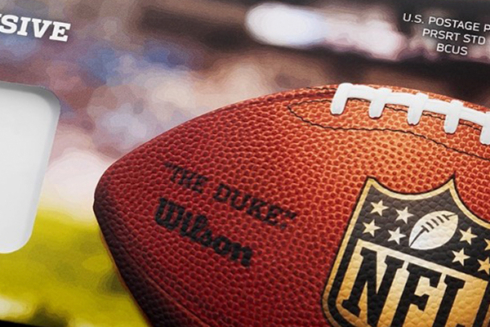

10. DEBOSS

On-Press Debossing is a technique where a design is pressed directly into the material during the printing process, creating a recessed, sunken effect. Unlike traditional debossing, which is typically done as a separate step, this method is performed directly on-press, a capability not easily achieved on most standard presses. This process speeds up production while delivering a high-quality, textured finish. The debossed areas interact with light, creating subtle shadows that enhance depth and give the design a striking visual dimension.

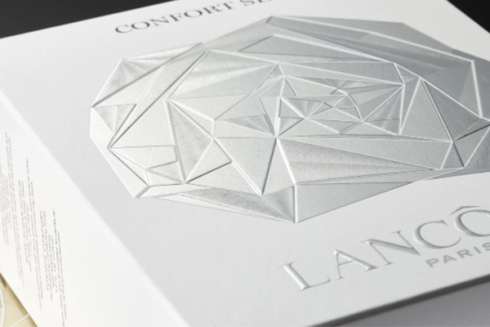

11. EMBOSS

Embossing is a classic technique that raises designs on the packaging surface. This finish adds a premium tactile element that enhances both the visual and physical experience of the packaging. The embossing levels as single level, multi-level and sculpted to depict definition and textures in a realistic manner. Ideal for luxury packaging across all sectors, particularly where brand logos or key design elements need to stand out.

12. DIGITAL FOILS

Digital Foils seamlessly merges the precision of digital printing with the elegance of foil finishes, offering a modern, efficient way to incorporate metallic elements into packaging. Unlike traditional foil stamping methods, digital foiling does not require the use of a die or heat. Digital foils also allow for variable data printing, enabling unique designs across individual pieces without the need for retooling. The result is a brilliant, polished effect that enhances the visual appeal of the packaging, delivering a bespoke, high-quality finish that can be customized quickly and efficiently.

13. METALLIC SHEEN

Silver and gold sheen coatings give any packaging a ritzy touch. These metallic sheens are shiny and bold without feeling too cold and metallic. Use under a base color to give it an extra gold glow or silver shimmer. If your budget doesn’t allow for foil stamping, metallic sheens are a great cost-effective alternative that delivers a similar look and feel.

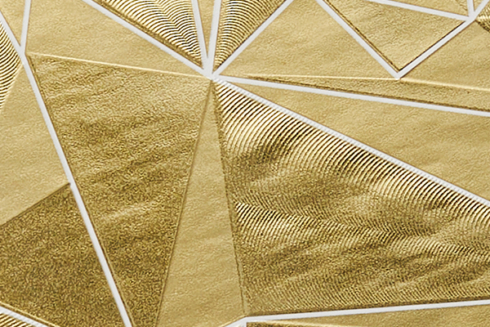

14. MICROETCHING

Microetching is a precise technique that creates ultra-fine patterns on the surface of foil, adding a delicate texture that can be both seen and felt. This process involves etching intricate designs into the material, much like the fine engravings. The result is a subtle, tactile effect that adds depth without overpowering the design. Microetching offers a refined detail that invites closer inspection, giving the packaging an exclusive, handcrafted feel.

15. PEARLESCENT / IRIODIN COATING

If a luxurious shimmer appearance is what you’re looking for, then a pearlescent coating is the way to go. Pearlescent coatings can be either aqueous or UV-based. Depending on the variation and size of the micron particle, the pearlescent coating can have a more dramatic or subtle effect. The result is a refined finish that enhances the overall aesthetic, offering a rich look that elevates the

16. RETICULATING

Another way to achieve a signature visual and/or tactile effect is with an on-press process called reticulation. This effect is achieved when a spot varnish and an overall UV coating is applied. When these two are mixed, there is a chemical reaction that results in a tactile and visual effect. Different pattern effects can be achieved, making it stand out in a crowded marketplace. Perfect for limited-edition products or promotional packaging where uniqueness and exclusivity are key selling points.

17. SCENT

Scent Coating integrates fragrance directly into the packaging through a specialized microencapsulated coating process that is activated upon rub or scratch to release the scent. The scents come in a variety of standard aromas or can be developed as a custom scent. By layering scent with visual and tactile design, scent coating adds a memorable, multi-sensory experience that captivates the consumer.

18. SOFT TOUCH

Soft Touch is applied through a specialized coating process that creates a smooth, velvety finish on packaging materials. The coating is applied either through UV or aqueous methods, leaving behind a subtle, matte texture reminiscent of suede or soft leather. This process not only enhances the tactile experience but also adds durability and resistance to fingerprints and smudges, maintaining the package’s premium look over time. The result is a luxurious finish that elevates the entire presentation, making the packaging feel high-end and inviting to the touch.

19. TACTILE COATING

Tactile Coating adds various textures to the packaging surface, enhancing grip and sensory appeal. This finish can range from smooth and silky to rough and gritty, depending on the desired effect. Suitable for products where the feel of the packaging is as important as the visual appeal, such as in the beauty, wellness, and spirits industries.

20. VARIABLE FOIL

Variable Foil achieved through digital enhancement is a way to add variable imaging on a printed piece to make each package Unique. This technique is perfect for adding visual interest and complexity to packaging. Ideal for luxury packaging that needs to convey creativity and innovation, particularly in limited-edition or high-value products.

Elevate Your Brand With JohnsByrne

In the world of premium packaging, the details matter. The right coating or finish can transform your packaging from ordinary to extraordinary, creating a memorable experience that resonates with consumers and enhances your brand’s value. At JohnsByrne, we combine decades of expertise with cutting-edge technology to deliver packaging solutions that not only meet but exceed expectations. Whether you’re looking to add a touch of luxury, create a sensory experience, or simply stand out on the shelf, our wide range of finishes and coatings offers endless possibilities.

Ready to elevate your packaging? Watch our video to see these finishes in action, and contact us today through our inquiry form to explore how our premium finishes can bring your brand vision to life.

Related Posts

When it comes to creating standout packaging, the folding and gluing process is the unsung hero that transforms flat, printed materials into eye-catching, functional packages. … Fast 5 Facts: Folding and Gluing: Bringing Packaging to Life!

This is simple: it’s not just a box. Every product deserves packaging that is both practical and exceptionally appealing. It should be structurally conceived so … Custom Product Packaging Solutions for Brand Loyalty and Preference

As a leading provider of premium packaging and custom print solutions to the Beauty & Wellness, Spirits, Financial Services, Consumer Products and Entertainment markets, JohnsByrne … Elevating Brands Through Advanced Digital Enhancement