Even for experienced industry professionals, printing and packaging terminology can seem unclear at times. At JohnsByrne, our aspiration is to simplify that aspect of your business so you can concentrate on creating great products.

When it comes to structural design, many packaging designers don’t realize just how many options are available to them. The possibilities are nearly endless. One way to create more striking and distinctive packaging is to experiment with various types of folding cartons. But how do you know which type of box or carton will work best with your design or packaging idea? While we can work with you to decide the perfect print process for your product, the various box types can be slightly confusing if you’re not familiar with the terminology. To get you started, we’ve rounded up some of the most widely used types of folding carton packaging:

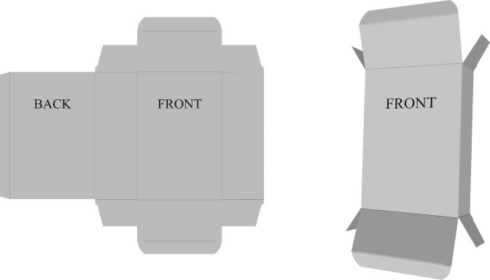

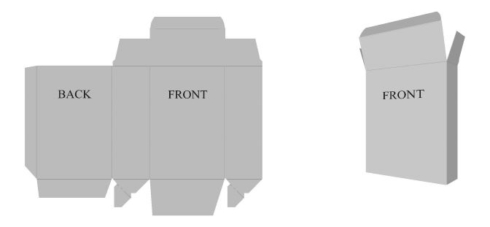

Straight Tuck Carton

This style features closure panels on both the top and bottom that swing from the front to tuck in the rear. The Straight Tuck Carton is the most universal and ideal canvas for a multitude of products and allows for maximum flexibility of finished.

This secondary package can also be manufactured with friction fit or slit locks for a more secure closure.

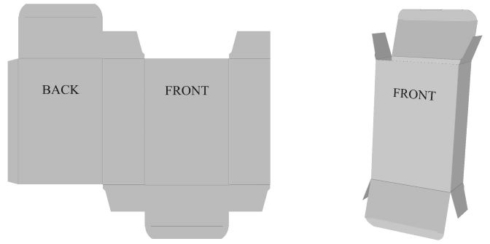

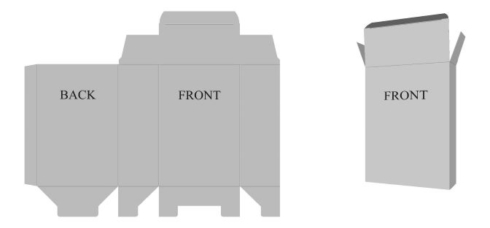

Reverse Tuck Carton

The Reverse Tuck Carton has a top closure that tucks in the opposite direction from the bottom closure. The SRT can be assembled through automation or manually and provides secure and easy closure. Tuck Cartons are typically used to package lightweight products. These cartons are typically shipped flat to the manufacturer, which makes them easy to transport and store.

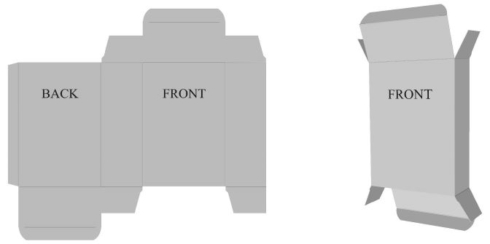

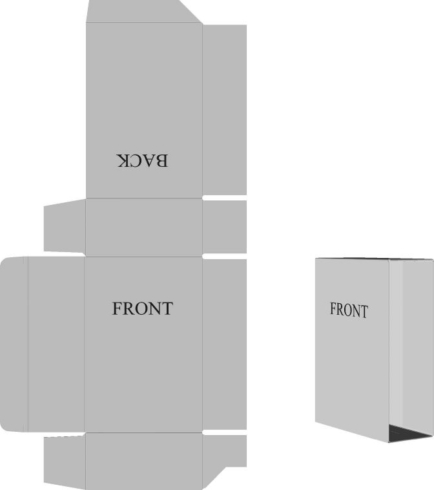

French Reverse Tuck

The French Reverse Tuck differs from the Reverse Tuck in that the top closure hinges off the front panel and tucks to the rear, while the bottom closure hinges off the rear and tucks to the front. French Reverse Tucks can have a slit bottom and a friction lock top. Other common combinations are slit lock top and bottom and friction lock top and bottom. This would be dependent on the weight of the product and opening experience preferences.

French Reverse Tuck cartons are used frequently in the cosmetic industry as they have a finished appearance and substantial latitude for graphic design.

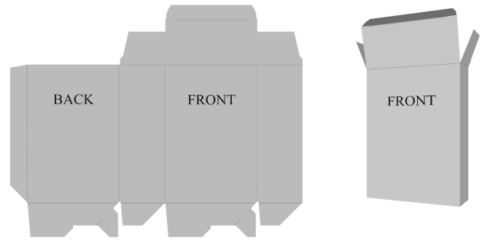

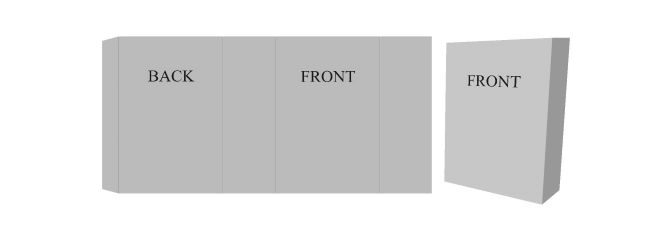

Tuck Top Auto Bottom

This pre-glued folding carton has a bottom constructed from multiple folded flaps which are positioned to form a composite bottom panel when the carton is assembled. The extended top flap is tucked in and held in place by friction or locked in position. Tucks may have either a friction fit or slit locks for a more secure closure. The glued bottom also allows the box to support heavier products and quick assembly.

Full Flap Auto Bottom

This type of carton provides a glued closure like the Auto Bottom above. It is designed for quick assembly and is typically designed for heavier products which is better supported with the large internal base panel. For example, sets of hair care products, or a wine and spirts VAP set (Value Added Package).

1-2-3 Snap Lock Bottom

Sometimes referred to as 1-2-3 closure, it is used almost exclusively as a bottom closure, generally in combination with a tuck top closure. This is a hand-erected and closed style. This style is commonly used as the bottom closure for shallow, tube style products. The Snap Lock Bottom offers additional security and is ideal for heavier products. This carton style fills the gap between a Tuck Bottom and Auto Bottom Carton in terms of cost, strength, and assembly.

Straight Tuck with 5th Panel / Book Style

This style is modeled after the straight tuck carton and contains and extra fold out panel, referred to as the 5th panel. This additional panel is use for extra copy and a replacement to additional printed pamphlets or brochures in the package. Window elements can be added to this panel to create creative show-through elements as well to complement brand identities.

Finished Edge Slipcase

A Finished Edge Slipcase can be used when an open end is preferred. The most memorable exposure one would have to this piece would be a DVD or Blu-ray collection. Some other use scenarios would be having a sleeve over the top of a side load Finished Edge Slipcase. Also, a combination of two slipcases with one of them being shorter than another would lead to a nice sideload package with reveal.

Sleeve

A sleeve is often used to keep a package closed (ex: a two-piece box) or can be used to cover a tray (ex: a slipcase or frame view tray). It can also be used for extra graphics or a limited time promotional copy on the exterior or an existing package. For example, during a holiday promotion it can be used, then removed once the promotion ends.

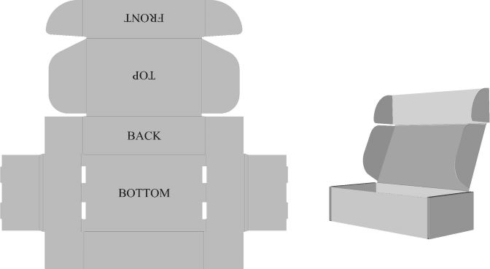

Front Lock Mailer

A front lock mailer is a an easy-to-assemble glueless carton that provides protection to the package and contents inside. The tabs on the variation shown form a secure closure. This structure can be highly decorated using premium finishes and materials to bring it into the luxury space.

Bringing You Customized Print Solutions

JohnsByrne’s customized print and packaging solutions are possible due to the extensive knowledge and experience of our team. From the outset we are able to collaborate and understand the final look you want to achieve and our experience and ingenuity is there to create the right solution with the right materials. Contact us today to learn more about our range custom boxes, cartons and other containers.

Related Posts

A cornerstone of secondary packaging is the paperboard folding carton. Paperboard stock is specifically formulated to crease easily and some stocks are purchased for their … The Folding Carton Manufacturing Process

With the holidays in full swing, we’re excited to bring back our annual 12 Days of JB Faves! Once again, we have an array of … ‘12 Days of JohnsByrne Faves’ 2023 Holiday Packaging

JohnsByrne is pleased to announce that we’ve received an impressive seven awards in the categories of Innovation and Sustainability at the 80th Anniversary of the … Unboxing Award-Winning Innovative & Sustainable Packaging